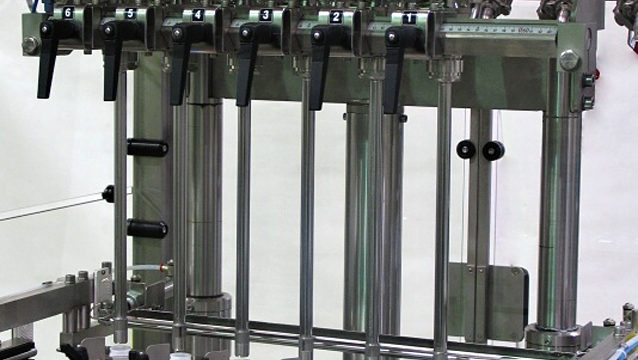

Linear fillers for bottles and jerry cans PLF

Automatic linear machines designed for filling of bottles and jerry cans with precise measuring of the filled dose. Non-contact filling with the possibility of filling above, on or below the surface. Fully automated control, high accuracy of filled dose measurement, simple operation and high quality design and workmanship ensure high efficiency of operation of these machines.

* typical values. An individual solution can be prepared after consultation with ALTEC’s technical department.