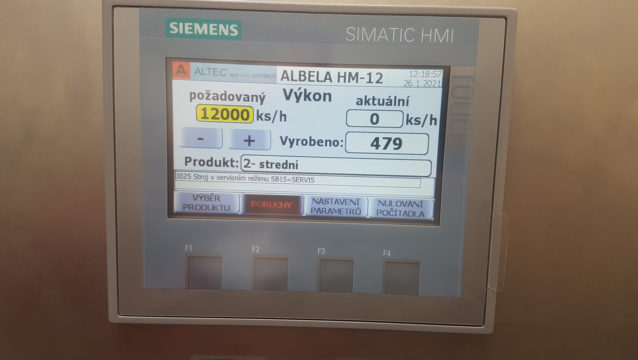

Rotary labeller - ALBELA HM

Automatic equipment for application of wraparound labels onto cylindrical containers using „HOTMELT“.

Rotary labeling machine Albela HM applies wraparound labels from precut paper or plastic material onto cylindrical containers from glass, plastic or tin cans.

Fully automated control, a modern glue application system, simple operation and quality design and workmanship ensure high efficiency of operation of these devices.

* typical values. An individual solution can be prepared after consultation with ALTEC’s technical department.