Bottle and pack conveyors

Automatic systems for transporting primary and secondary packaging in bottling lines. These include bottles and other filled packaging, as well as group packaging of products such as plastic crates, cartons or shrinkpacks.

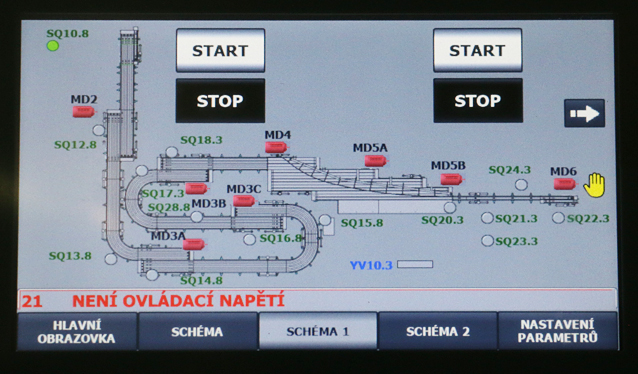

Different levels of automation, simple operation and high-quality design and workmanship ensure high efficiency in the operation of the conveyors and thus the filling lines.

* typical values. An individual solution can be prepared after consultation with ALTEC’s technical department.