The most common types of closures and their processing

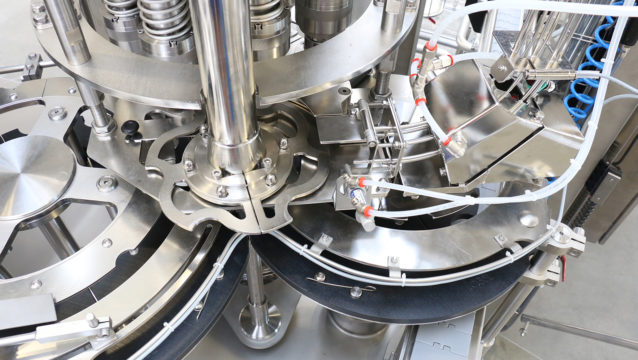

Design for plastic screw caps: the cap is usually gripped by the capping head from the caps feeding star. In the next step, the head with the cap seats on the bottle and the bottle is closed (system „pick and place“). In some cases, the cap is placed on the neck of the bottle at the inlet star of the capping machine, the capping head then seats on the cap and the bottle is capped (system „pick off“). The capping head is fitted with magnetic coupling. This allows the capping torque to be adjusted for a safe and quality closing of the bottle.

The closures are usually oriented and transported using our sorter TZP, optionally Sortec.

Design for aluminium roll-on caps: the cap is placed on the neck of the bottle at the inlet star of the capper, the capping head then seats on the cap and the bottle is closed (system „pick off“). The capping head is fitted with rollers that roll-on the thread and the safety ring on the neck of the bottle.

The closures are usually oriented and transported using our sorter TZP, optionally Sortec.

Design for plastic press-on caps: the cap is either placed on the neck of the bottle in the inlet star of the capper, the capping head then seats on the cap and closes the bottle (system „pick off“), or the cap is gripped by the capping head from the feeding star of the caps. In the next step, the head with the cap seats on the bottle and the bottle is closed (system „pick and place“). The capping head is equipped with a mechanism for fixing the cap on the neck of the bottle and then pressing it on.

The closures are usually oriented and transported using our sorter TZP, optionally Sortec.

Design for crown caps: the capper is equipped with system „pick and place“ feeding of caps for precise guidance of the cap into the capping head and onto the bottle neck.

The closures are usually oriented and transported using our sorter TZP.